We have a vast experience in designing SMT stecils and we have done 90000+ stencils so far. We have an experience in handling Gerber data format of 274, 274x, ODB++ and IPC-2581, also we able to generate Gerber files from data sheets. We create a Library for specific customers and it will ensure consistency in the designing process. Based on the customer feedback, we continuously track and update our libraries. This will ensure the better yield in the soldering process.

Our design team go extra mile in supporting our customers, if there is a new component from the development then we check the recommended aperture design from the Component Manufacturers and we will ensure that has been taken care of in the designing process.

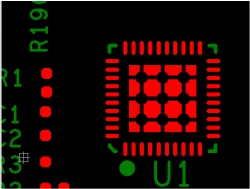

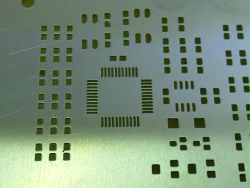

By default, we check the accuracy in the Gerber data and we flag our customers when the paste layer miss any components or Paste layer is under or over size than the Copper layer. If there is a PTH on the paste layer, we will consider for pin in paste process and we flag this to customers.

Every stencil designs are inspected by Next level Senior designers and this will ensure the error free design all the time.

Why Us?

Design Library and continuous updation in the guideline will give you consistent results. Every designer goes through the same process and ensures that the instructions are followed all the time.

Our extensive knowledge in stencil design gives better yields. We design Pin-in-Paste and multi-step stencils based on assembly requirements and suggest the best foil thickness.

Every stencil goes under Design Rule Check and Area Ratio verification. Customers receive a complete area ratio report with flagged unnecessary apertures.